Introduction

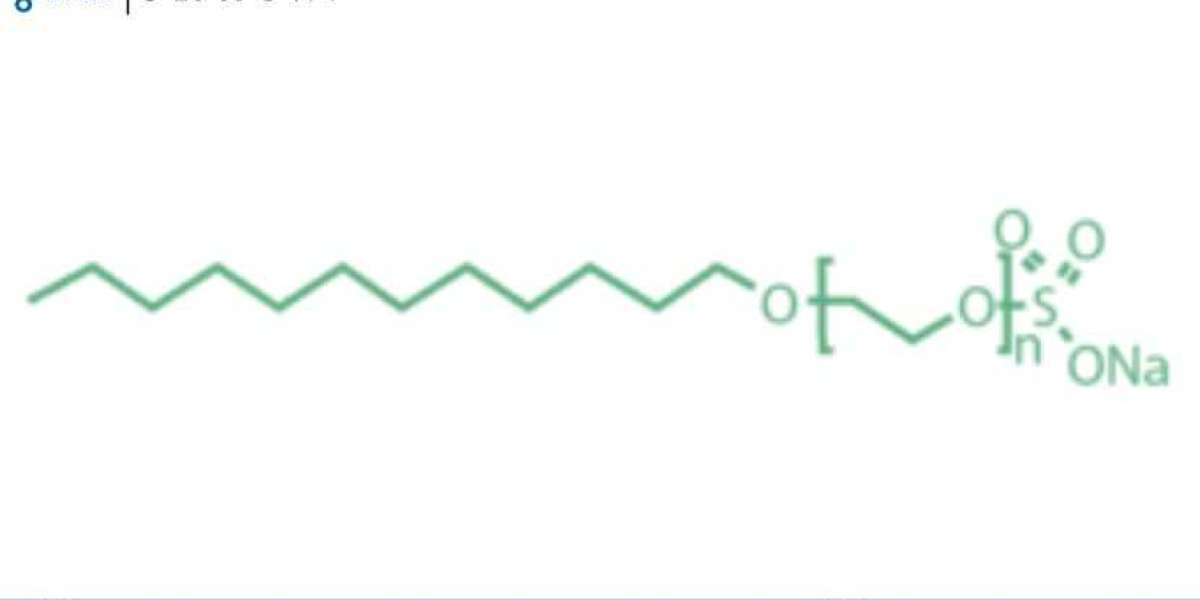

Alkyl Ether Sulfates (AES) are an important class of surfactants used extensively in the personal care and household products industries. They are known for their excellent foaming properties, mildness, and effectiveness as detergents. Commonly found in shampoos, soaps, and cleaning products, AES offer a balance of performance and gentle handling. With the rising demand for these products globally, establishing a dedicated Alkyl Ether Sulfates manufacturing plant project report is becoming increasingly significant. This article provides an in-depth overview of a project to build an AES manufacturing plant, outlining its objectives, production processes, benefits, and addressing frequently asked questions.

Project Overview

Objectives

The Alkyl Ether Sulfates Manufacturing Plant Project aims to achieve several key objectives:

- Meeting Market Demand: Ensuring a stable and high-quality supply of AES to satisfy the growing needs of personal care and household product manufacturers.

- Quality Assurance: Producing AES that adheres to stringent industry standards for performance, safety, and environmental impact.

- Economic Impact: Creating job opportunities, boosting local economies, and attracting further investments.

- Innovation and Sustainability: Implementing advanced technologies and sustainable practices to enhance production efficiency and reduce environmental impact.

Get a Free Sample Report with Table of Contents @ https://www.expertmarketresearch.com/prefeasibility-reports/alkyl-ether-sulfates-manufacturing-plant-project-report/requestsample

Location and Infrastructure

Choosing the right location for the AES manufacturing plant is essential for operational success. Key factors include:

- Proximity to Raw Materials: Being near suppliers of essential chemicals such as alcohol ethoxylates and sulfuric acid helps reduce transportation costs and ensures a reliable supply.

- Regulatory Environment: A location with favorable regulatory conditions simplifies the approval process and operational compliance.

- Infrastructure: Adequate infrastructure, including transportation, utilities, and waste management systems, supports efficient and smooth plant operations.

The plant will be equipped with modern facilities:

- Production Lines: Designed for high efficiency in the synthesis and processing of AES.

- Quality Control Labs: To ensure that the AES produced meet industry standards for purity and performance.

- Storage Facilities: For raw materials and finished products, ensuring proper inventory management and distribution.

Production Process

Raw Material Sourcing

The production of Alkyl Ether Sulfates begins with sourcing high-quality raw materials:

- Alcohol Ethoxylates: The primary reactant in the synthesis of AES, usually derived from petrochemical or bio-based sources.

- Sulfuric Acid: Used to sulfated the ethoxylates and convert them into AES.

Manufacturing Process

The manufacturing process for Alkyl Ether Sulfates involves several key steps:

Preparation of Raw Materials: Alcohol ethoxylates and sulfuric acid are prepared and pre-treated as necessary to ensure purity and efficiency in the reaction process.

Sulfation Reaction: The prepared alcohol ethoxylates are reacted with sulfuric acid in a controlled environment. This step converts the ethoxylates into Alkyl Ether Sulfates through a process known as sulfation.

Neutralization and Washing: The reaction mixture is neutralized to balance the pH and then washed to remove any residual acid and by-products.

Concentration and Purification: The mixture is concentrated to achieve the desired consistency and purity. Further purification steps may be employed to ensure the final product meets industry standards.

Quality Testing: The final product undergoes rigorous quality testing to ensure it meets specifications for performance, safety, and purity.

Packaging and Storage: The finished Alkyl Ether Sulfates are packaged in appropriate containers and stored under controlled conditions to maintain quality until distribution.

Quality Control

Maintaining high quality in AES production involves rigorous testing:

- Raw Material Testing: Ensuring that alcohol ethoxylates and sulfuric acid meet required specifications before use.

- In-process Monitoring: Continuous monitoring during the sulfation, neutralization, and purification processes to ensure consistency and adherence to specifications.

- Final Product Testing: Comprehensive tests on finished AES to confirm performance characteristics, safety, and purity.

Benefits of the Project

Economic Impact

The AES manufacturing plant will provide several economic benefits:

- Job Creation: The plant will create various employment opportunities, including roles in production, quality control, and administration.

- Local Business Growth: Increased demand for local suppliers and services can stimulate economic activity in the surrounding area.

- Investment Attraction: The project can attract additional investments and partnerships, contributing to regional economic development.

Health and Safety

The plant will contribute to health and safety in the following ways:

- High-Quality Products: Producing high-quality AES ensures safe and effective ingredients for personal care and cleaning products.

- Safe Manufacturing Practices: Implementing stringent safety protocols in the plant to ensure a safe working environment and minimize risks.

Environmental and Sustainability Benefits

The project supports environmental sustainability through:

- Efficient Resource Use: Advanced manufacturing technologies and practices improve resource efficiency and reduce waste.

- Waste Management: Effective waste management systems handle by-products and residues responsibly.

- Energy Efficiency: Modern production techniques aim to reduce energy consumption and lower the plant’s carbon footprint.

Technological Advancements

The plant will leverage technological advancements:

- Innovation: Adoption of cutting-edge manufacturing technologies to enhance efficiency and product quality.

- Research and Development: Opportunities for ongoing RD to improve AES properties and explore new applications.

FAQ

What are Alkyl Ether Sulfates?

Alkyl Ether Sulfates (AES) are surfactants derived from alcohol ethoxylates and sulfuric acid. They are used in personal care and household products for their foaming, cleaning, and emulsifying properties.

Why is a new Alkyl Ether Sulfates manufacturing plant needed?

A new AES manufacturing plant is needed to meet the increasing demand for these surfactants in various industries. The plant will ensure a reliable supply, support economic growth, and contribute to advancements in product formulations.

How does the Alkyl Ether Sulfates manufacturing process work?

The manufacturing process involves preparing alcohol ethoxylates, reacting them with sulfuric acid to produce AES, neutralizing and washing the mixture, concentrating and purifying the product, and conducting quality testing before packaging and storage.

What are the key quality control measures in place?

Quality control measures include testing raw materials for quality, monitoring the production process, and conducting comprehensive tests on finished AES to ensure they meet industry standards for performance, safety, and purity.

What are the environmental considerations for the plant?

Environmental considerations include efficient use of resources, effective waste management, and energy-efficient production technologies to minimize the plant’s environmental impact and support sustainability.

How will the plant impact the local community?

The plant will positively impact the local community by creating jobs, stimulating local businesses, and providing high-quality ingredients for personal care and cleaning products. It also offers opportunities for skill development and contributes to regional economic growth.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/